Many people may not be able to distinguish between printed socks and ordinary socks, actually, there are many fundamental differences between these two. This article will give you an idea of these differences and let you know how to design and customize.

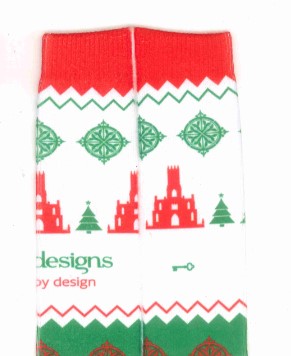

First, the principle of printed socks is similar to that of ordinary printing. Socks are like white papers, and the pattern will be printed by the printer, rather than knitted through the thread (you can learn more about knitting socks).

So you can almost understand that printed socks are socks in which the special machine print the pattern, and they are usually made in two ways: heat transfer printing and 3D printing.

Why do you choose printed socks?

Ordinary knitted socks often have many limitations, such as the number of stitches in a circle, the number of colours less than 6, the design is not exquisite enough, and the long-producing time. The main reasons for choosing printed socks is that without these limitations, they can have almost unlimited colours, patterns are more elaborate than knitted socks and less producing time.

Heat Transfer Printing Socks:

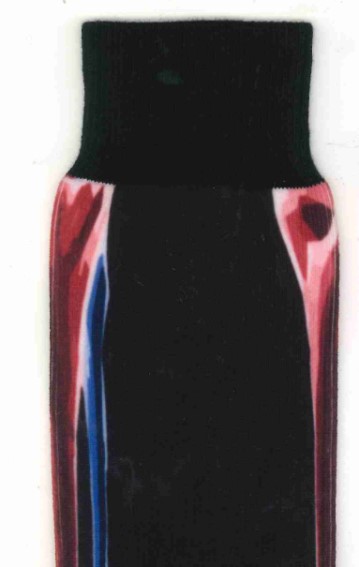

Heat transfer printing socks do not mean the patterns are directly printed on socks, but with a special paper (transfer film) as the medium. The pattern is printed on the transfer film, and then the socks are attached tightly to that transfer film. After high temperature and high-pressure treatment, the pattern on the transfer film will be integrated with socks to achieve the printing effect.

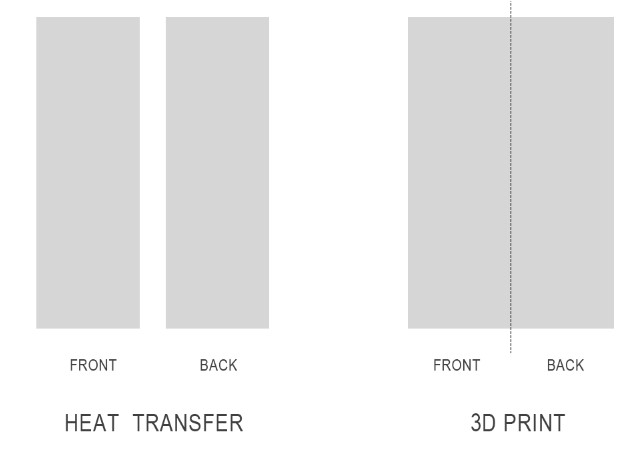

It should be noted that due to technical limitations, only be printed for twice can a pair of socks be completely make out, which requires the designs of both front side and back side. Besides, another problem with printed socks is that a line will inevitably appear in the side of socks, that because socks are not like papers, it has a certain thickness so that part of socks cannot fully be attached with the transfer film.

Of course, as shown in the following figure, this line can be avoided by design. We can set a solid colour on the side, and make it same with the background colour of socks, this line will disappear. If you pursue perfection, you can use this method.

Of course, if you want your design to be more perfect, you can choose 3D printing socks, which also means more customizing costs.

3D Printed Socks:

The principle of 3D printing socks is that patterns are printed directly through the machine on a sock sleeved on a cylinder, and all patterns are coherent to each other. By the way, only one design drawing is requested in the designing process. Since without the problem of “sideline”, 3D printing socks are more perfect than heat transfer printing socks, but it takes more time and cost.

How should Design Printed Socks?

For heat transfer printing socks, you need to design both front and back patterns because it must be printed in the front side and back side.

For 3D printed socks, one design drawing is enough since the pattern is printed directly on the socks.

We have more articles about socks customization/design:

Design socks with free templates