About socks customization, it is very simple, that is: you have socks design, we help you turn it into reality.

Of course, as a socks factory, there is a lot of work for us to do to produce a perfect pair of socks, which is no need for you to concern about. There is also a custom sock guide.

What do we do?

- About socks raw materials, including colours, different materials, sizes of yarn, and ratios of

- Regarding the pattern of socks, we need to encode and let the machine recognize.

- About socks, size, weight, design, requirements of socks quality.

- Socks packaging, own brand/label, outer packaging...

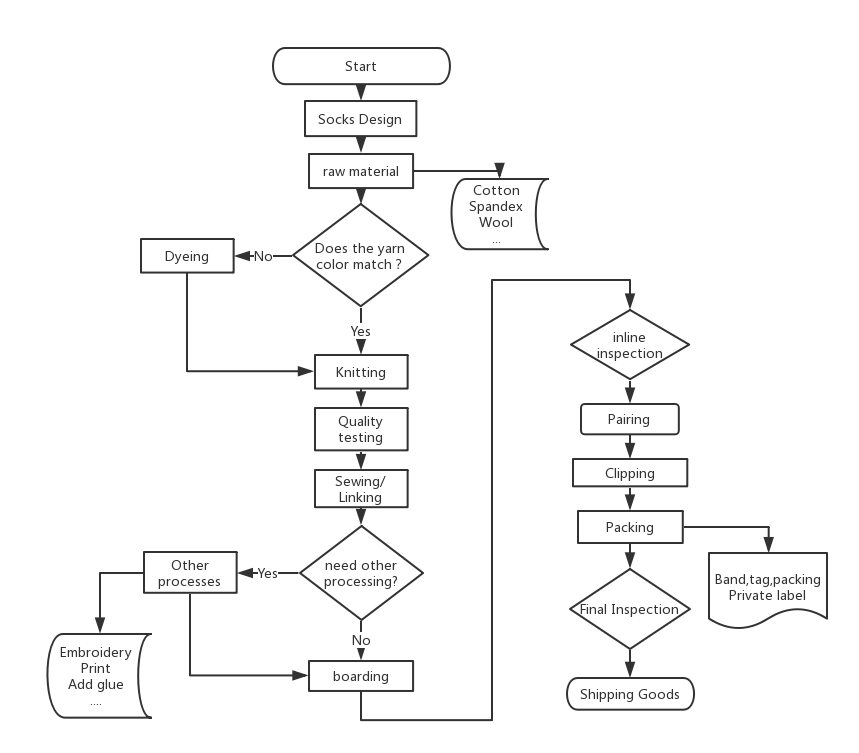

Socks manufacturing involves many detailed processes, from design to production and to transportation, each of which must be coordinated to ensure the quality and productivity of the socks.

Socks Production Flow Chart

The entire socks production process involves many steps, each requiring some time to prepare. I simplify them into six steps.

- Preparation, design, raw materials, machine coding, etc.

- Knitting socks

- Post-processing, sewing socks, embroidery / printing / dispensing / sewing

- Boarding

- Customized packaging/label production and packaging

- Socks transport

1 Preparation, Design, Raw Materials, Machine Coding, etc.

The design of the socks comes from clients, we can also help them design, but they need to provide their own ideas, of course, we also provide professional socks design templates, and we need to match the colour and yarn.

Preparation of raw materials: According to customer requirements and designing drawings, we prepare yarns, such as veil, polyester, chemical fibre and so on. If necessary, dyed yarns are required. The quality and cost of socks are highly depended on raw materials. We will select the right yarn for our customers' needs.

Convert to machine code: We can't directly input the design into the sock machine and we need to transform it into a recognizable file for the hosiery machine, which will eventually be converted into individual pixels, corresponding to each needle of the machine. Different machines have different numbers of needles, usually, there are 96N, 144N, 168N, 200N and so on. Due to the limitation of the number of stitches, the socks cannot be shown fine patterns or be graduating.

2 Knit Socks

In the first step, we prepared the yarns and made the machine code. We need to weave the yarns of each colour in a certain order, which looks boring and difficult, but it's easy for a machine.

We can get the prototype of the socks by knitting, but still have some work to do: checking the line of the socks, trimming and correcting some colours, most of which are done during the phase of proofing.

3 Post-processing, Sewing Socks, Embroidery / Printing / Dispensing / Sewing

Through the hosiery machine, we can see that the socks are now just a cylindrical tube that is not really finished. We need to use a sewing machine to connect the toes of the socks. Usually, this step is done by the machine, but sometimes it is done manually, which will take a lot of time, but it is worth. Our workers will find some defective socks and remove them during the sewing process.

May a pair of attractive socks with a lot of technologies, we can add embroidery logos/logs to the socks, print them, and add glue to increase the slip resistance, or sew the pads...

4 Boarding

The Boarding is to keep the socks in shape and elasticity. We put the socks in the templates with the same size, then the machine will conduct certain extent of pressure/temperature and humidity, then the socks will become smoother.

5 Customized Packaging/Label Production and Packaging

In order to save time, it is not until now for us to start producing the customized package for clients, but usually at the time when the socks start to be produced. We offer socks customized service including package or labels, which no need for clients to worry about. Of course, they can choose printing companies by themselves, we will just make labels, and fix them on the socks.

6 Socks Transport

When everything is ready, the socks will be neatly placed in our warehouse, waiting for the train. Regarding transportation, clients can specify the shipping agent or we will arrange that.

Now, the work of producing socks is over. If you need to know more, you can read the following articles:

What Should You Pay Attention to When Customizing Printed Socks

Design socks with free templates

Design Socks Package With Free Lable/Tag Templates

Use free hand-painted template to design socks